Automatic weekly spec updates and quarterly License Plate recognition enhancements

Unmanned Inspection

NEW Quick Check® Inspection

Accelerate your alignment and tire business by checking the most important alignment angles and edge-to-edge tire tread automatically. New subscription-based software upgrades your equipment over the air to keep it running at its best.

Hunter Quick Check® Inspection

/

Quick Check® at a glance

New Inspection Live™ software subscription always has the latest inspection features

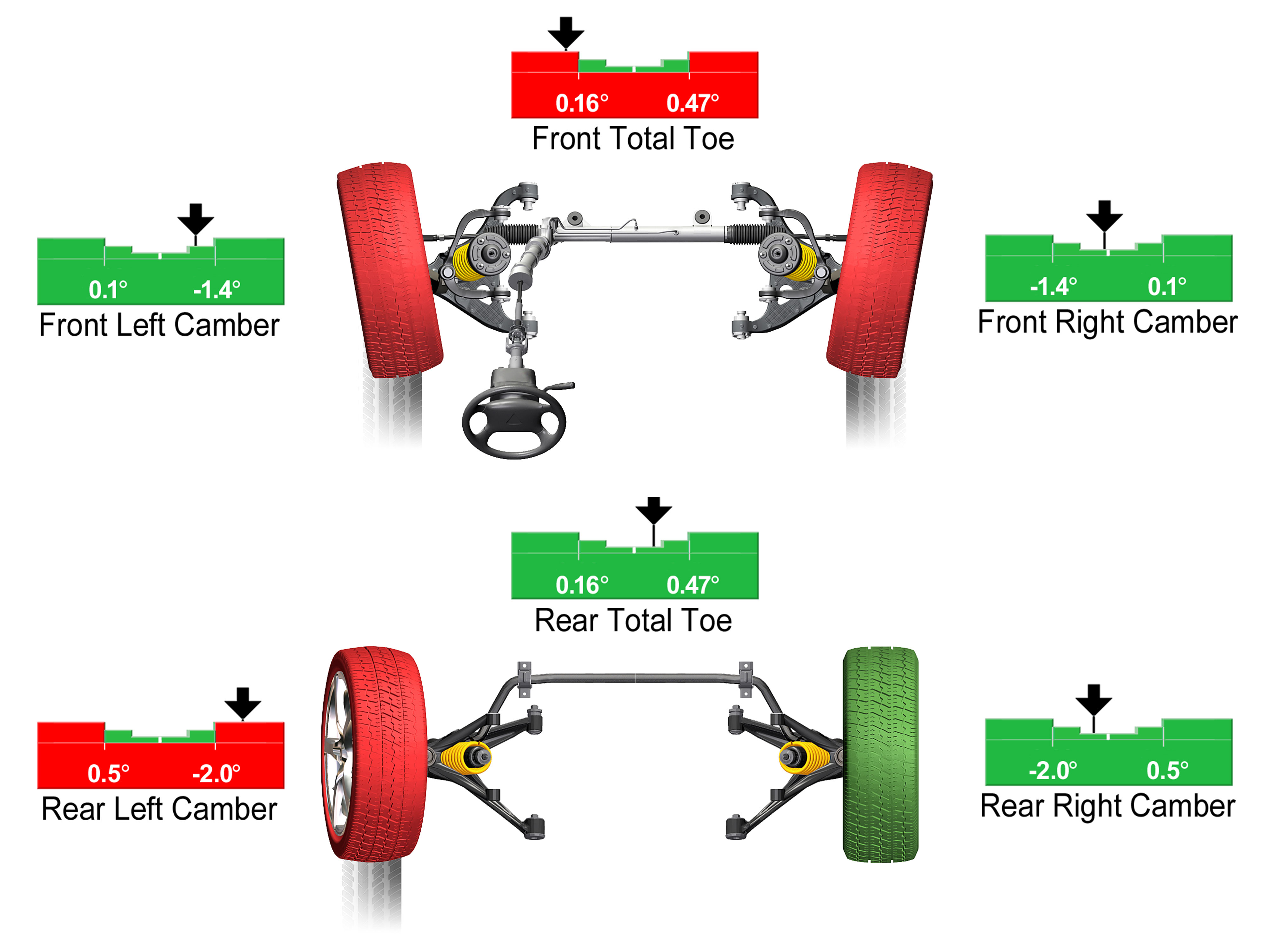

Total toe and camber angles measured

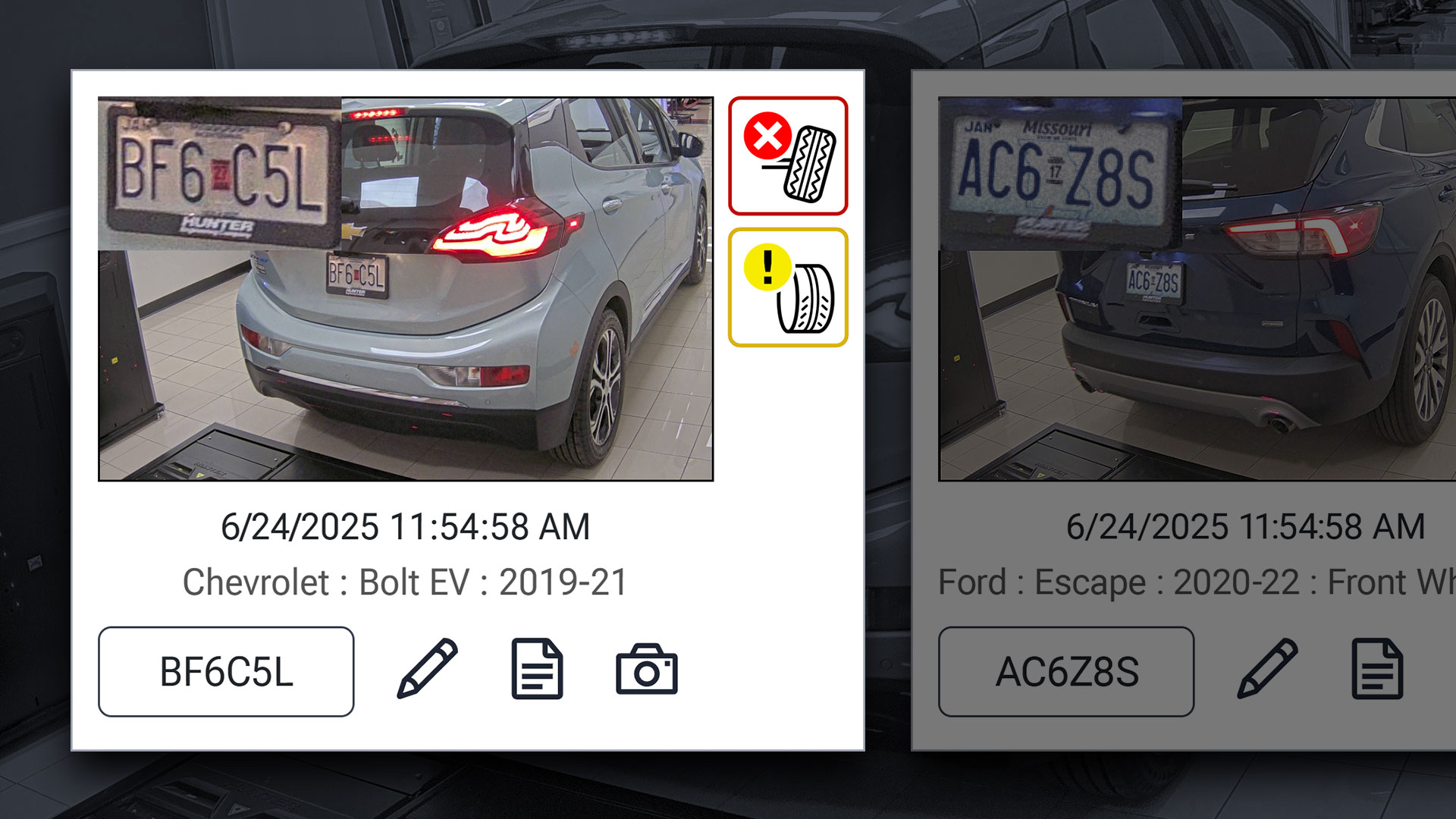

3D tire results help sell critical replacements

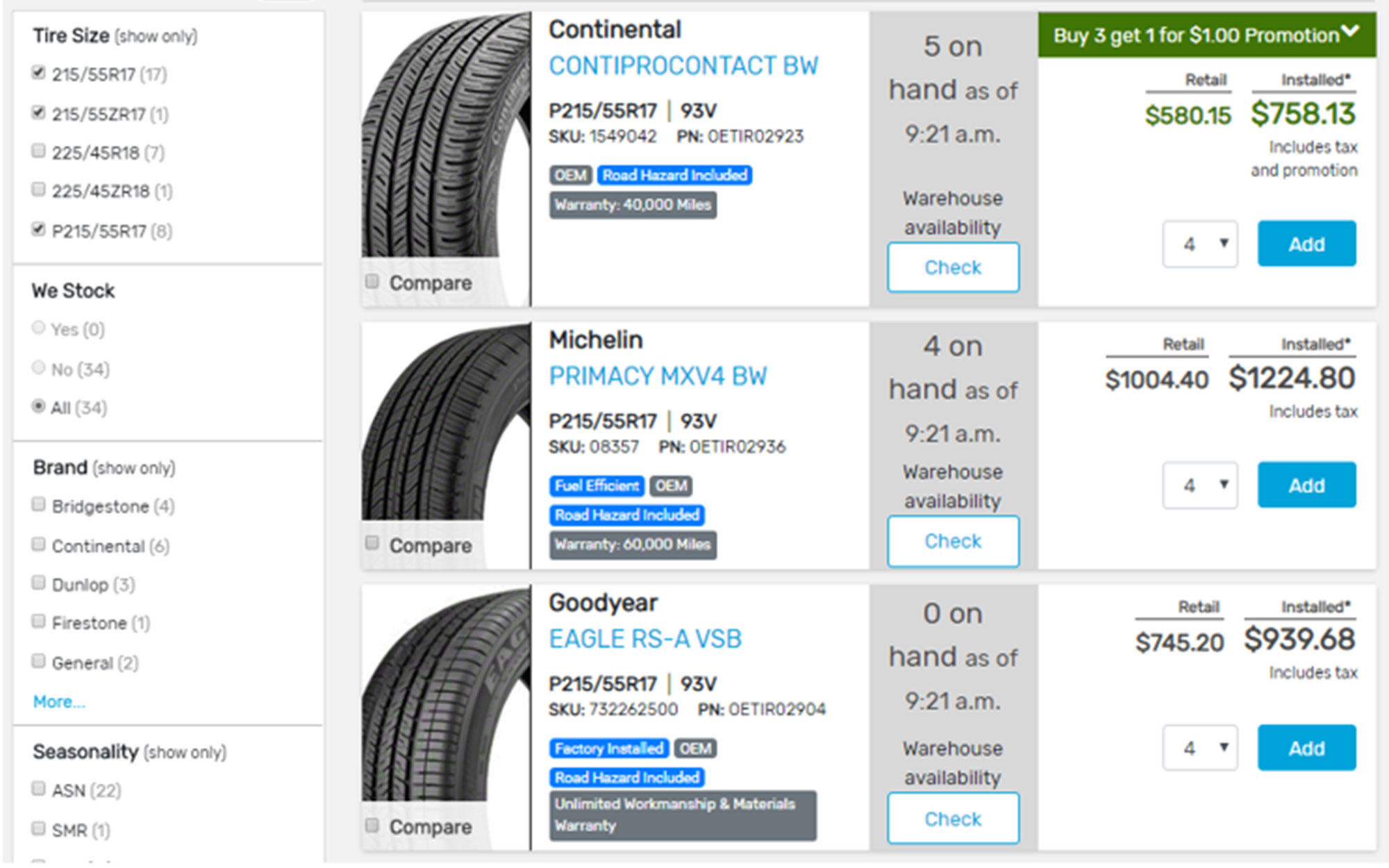

Results Display on HunterNet®, Flightboard™ and integrated partner portals to make it easy to share with customers

Capture 40+ images of each vehicle as it enters

Game-changing enhancements driven by Inspection Live™

Hunter's new seamless cloud-based software subscription platform now runs our Quick Check Drive® and Quick Tread Edge® inspection systems.

NEW Inspection Live™

Non-stop enhancements

Hunter's new inspection software subscription is now fully connected to the cloud. This subscription-based software automatically updates specs, license plate recognition, and body damage camera renewals, in addition to general product enhancements.

Powered by patented technology

High-definition cameras

Automatically identify vehicles, with optional full-vehicle 40+ photo capture

8 Cameras and 32 laser sensors

Accurately measure camber and total toe by taking 16 measurements per tire

3D tire tread mapping

400,000 data points across a 4" edge-to-edge section, producing unique 3D tire renders

Intelligent and fast

The new Inspection Live™ software is always up to date with the latest vehicle specs, license plate recognition, and software features.

Immediate results

Flightboard™ digital display shows customers their vehicle alignment and tire tread results in 7 seconds after driving through.

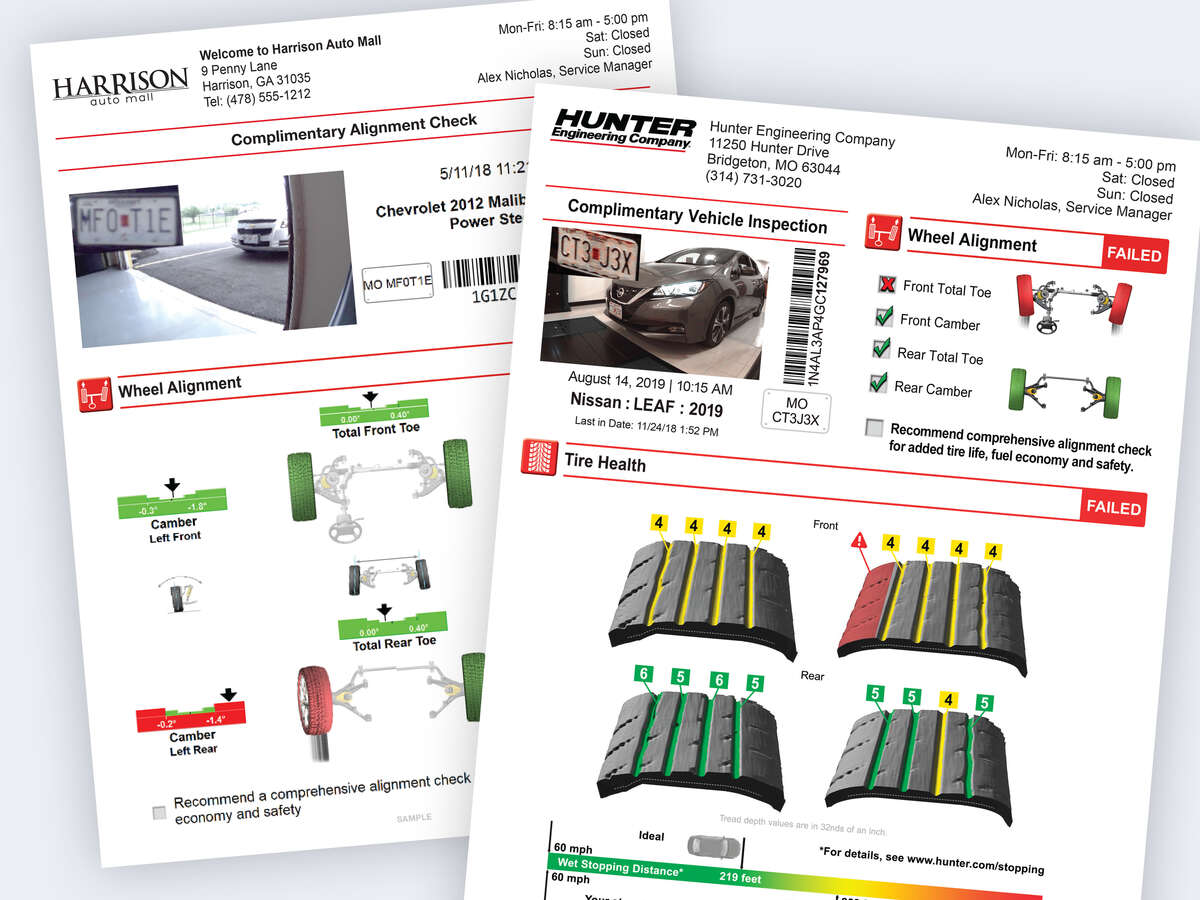

Quick Check Drive® automatically measures total toe and individual camber alignment angles on every vehicle, generating the most profitable opportunities.

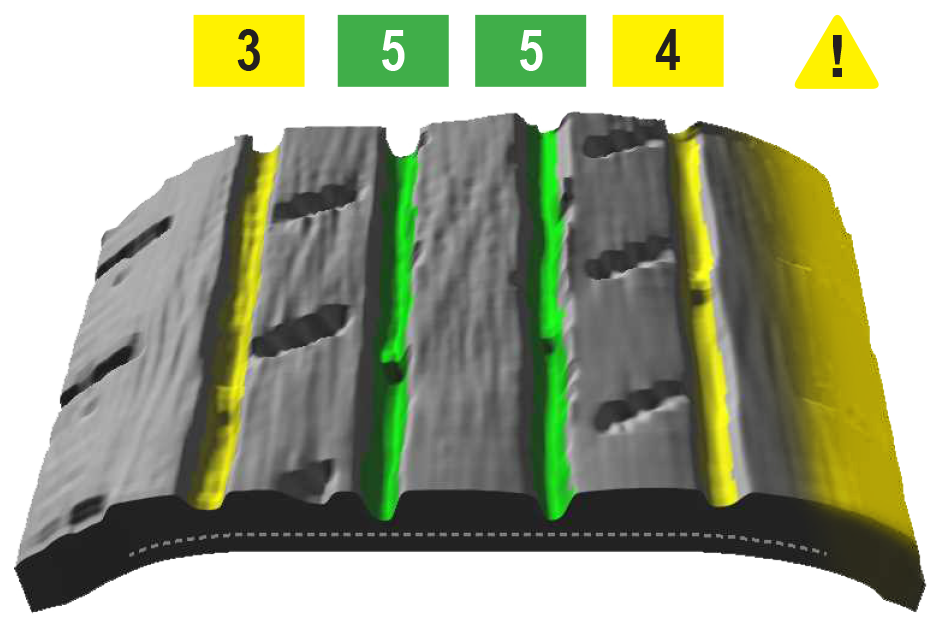

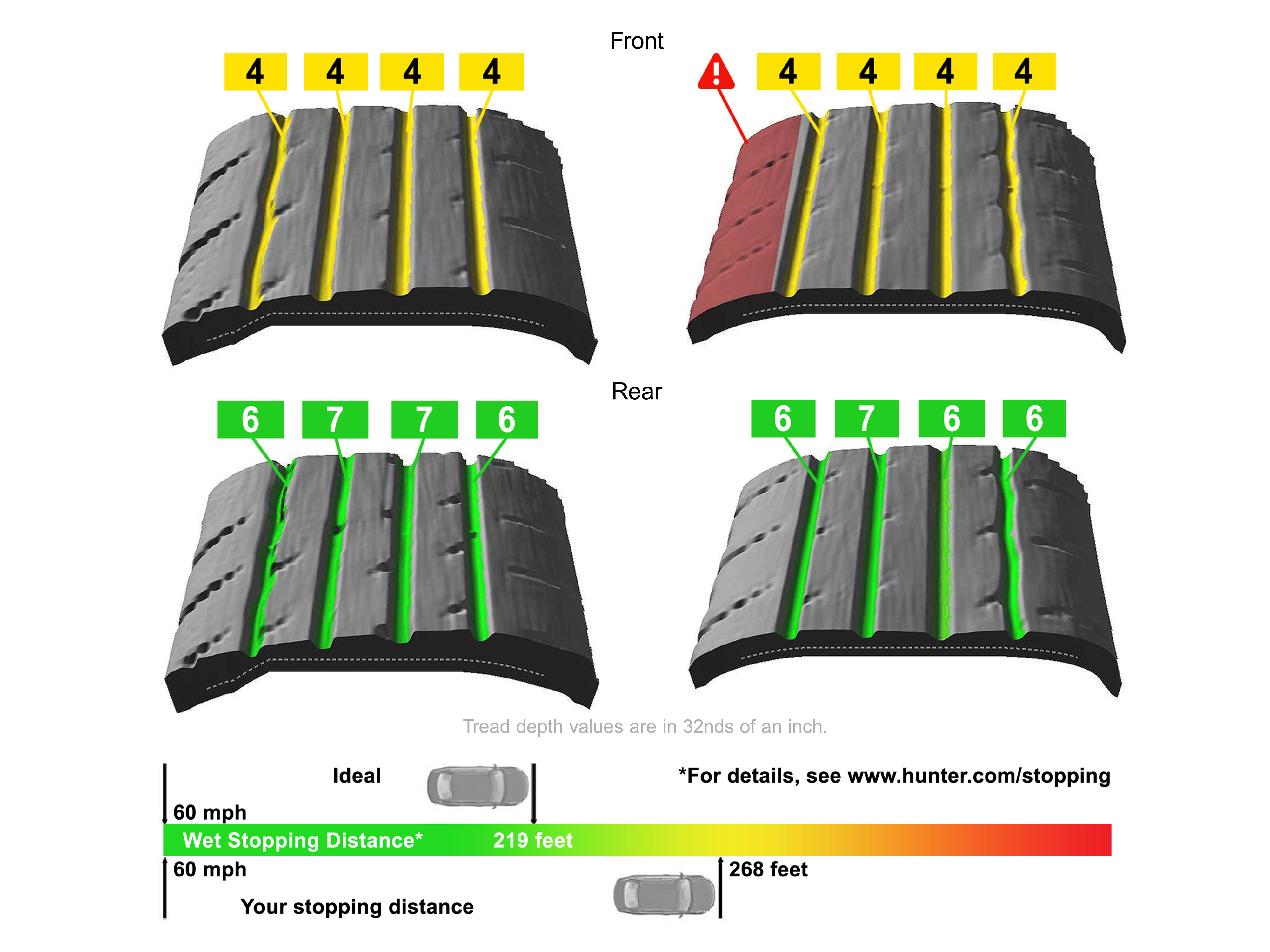

Quick Tread Edge® automatically measures tire tread depth including edge wear, generating 3D results to help sell critical replacements.

Approved and recommended by multiple OEM partners

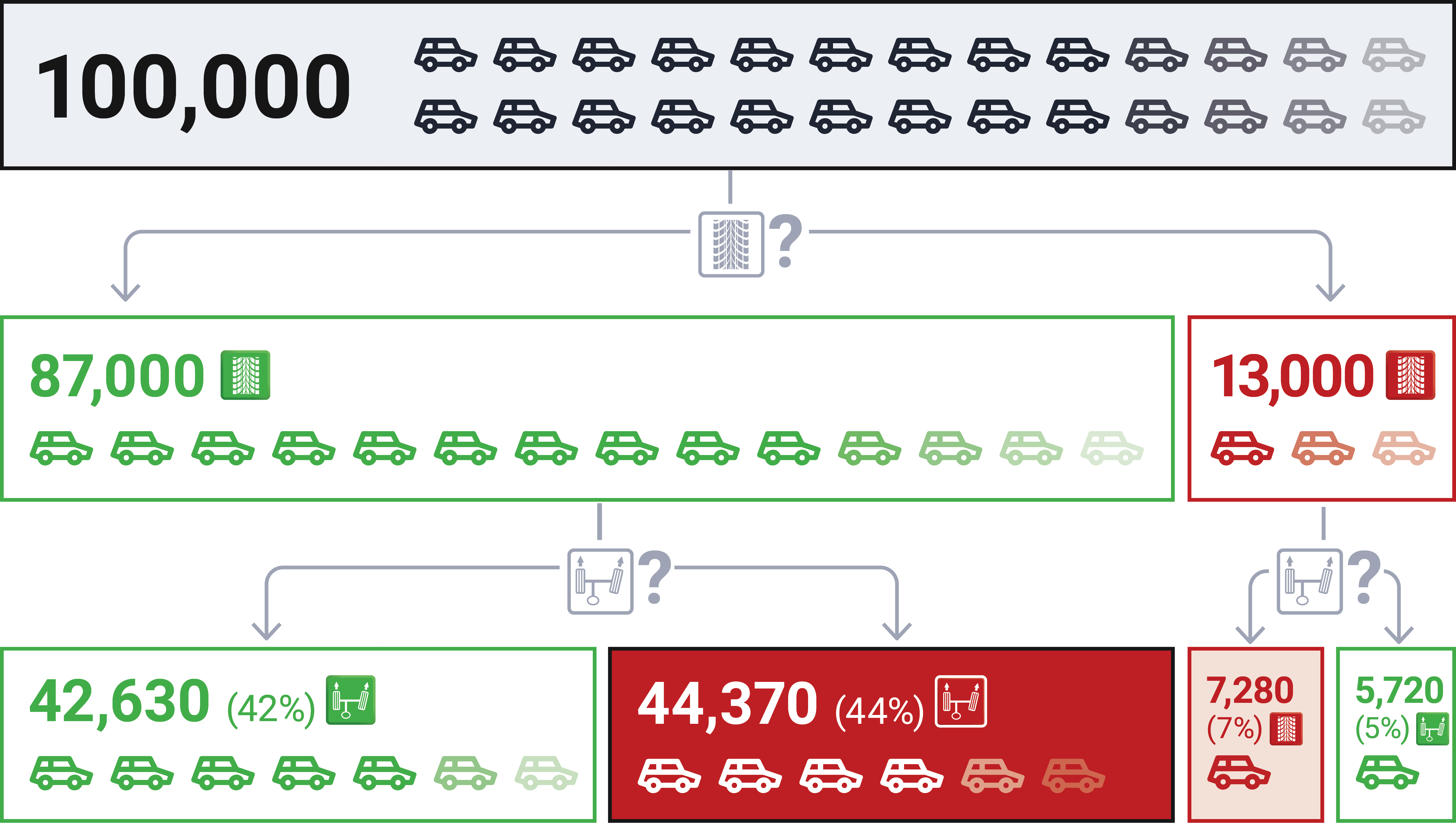

In a 100,000 vehicle study, 13% had irregular tire wear and may need a tire replacement soon. However, 44% had a failed alignment but were not yet showing tire wear. Offering an alignment before tread wear appears will help customers' tread last longer until they come back to you for a normal tire replacement.

Inform your customers on critical tire replacement services

Measuring tire tread edge wear is critical to proactive tire safety

A bald tire edge will affect wet weather traction, resulting in longer stopping distances and poor handling. If the edge portion of the contact patch has no tread, it cannot shed water.

Hunter enhances Quick Check® inspection with new cloud-based software

Hunter Engineering has announced the implementation of all-new cloud-based Inspection Live™ software for its Quick Check Drive® and Quick Check Edge® autonomous inspection system, streamlining existing processes and enabling new capabilities.

Quick Check Drive® at-a-glance

Hunter Engineering Company’s Quick Check Drive® system provides autonomous alignment audits powered by Hunter’s award-winning WinAlign® software.

"Quadruple" Alignment and Tire Sales

Real users are reporting quadrupled alignment and tire sales.

Santa Maria Dealerships turn inspection 180 degrees with Hunter unmanned inspection

Unmanned drive-through alignment and tread inspection in 15 seconds.

Morgan Auto Group quadruples tire and alignment sales

Joe Schlueter, Morgan Auto Group's VP of Fixed Operations, talks about the technological advantages and increased sales generated by Quick Check Drive® and Quick Tread Edge®.

Plaza Tire Service “adds gross profit and revenue”

Mark Rhodes, President of Plaza Tire Service®, has invested in Quick Check Drive® and Quick Tread Edge® systems at all of the new Plaza Tire locations being built and has the goal of putting the inspection system in each of Plaza’s 67 locations.

Pouring concrete was a no-brainer for Suntrup

Service Director of Suntrup Automotive Group, Elliot Silk, explains why Quick Check Drive® was the best investment made to help sales, retention and overall customer experience at Suntrup Kia South.

Quick Check Drive® technical overview

The completely unmanned system uses patented measurement technology to scan a vehicle as it drives through without stopping and provides total toe and individual camber measurements in seconds.

Hunter's Quick Check Drive® at Eddy's Toyota

Eddy's Toyota in Wichita, Kansas installed Quick Check Drive® automated alignment inspection systems in their service drives and saw an immediate return on investment, increasing their alignment sales by 300%!

Quick Check Drive® paid off in months at Jay Wolfe Toyota

Jay Wolfe Toyota of West County installed two Quick Check Drive® automated alignment inspection systems in their service drive and saw an immediate return on investment, by doubling their alignment business.

Quick Check Drive® at Cable-Dahmer Chevrolet

Cable-Dahmer Chevrolet of Independence, MO has equipped their service drive with Hunter's Quick Check Drive® automated alignment inspection system.

Alignment business doubled with Push Reports at Greenway

Greenway CDJR was looking for more insight into how their Hunter Engineering equipment was being utilized in their service drive to help drive their fixed operations business.

Results shown dependent on selected equipment. Displays used for Flightboard™ are sourced locally.

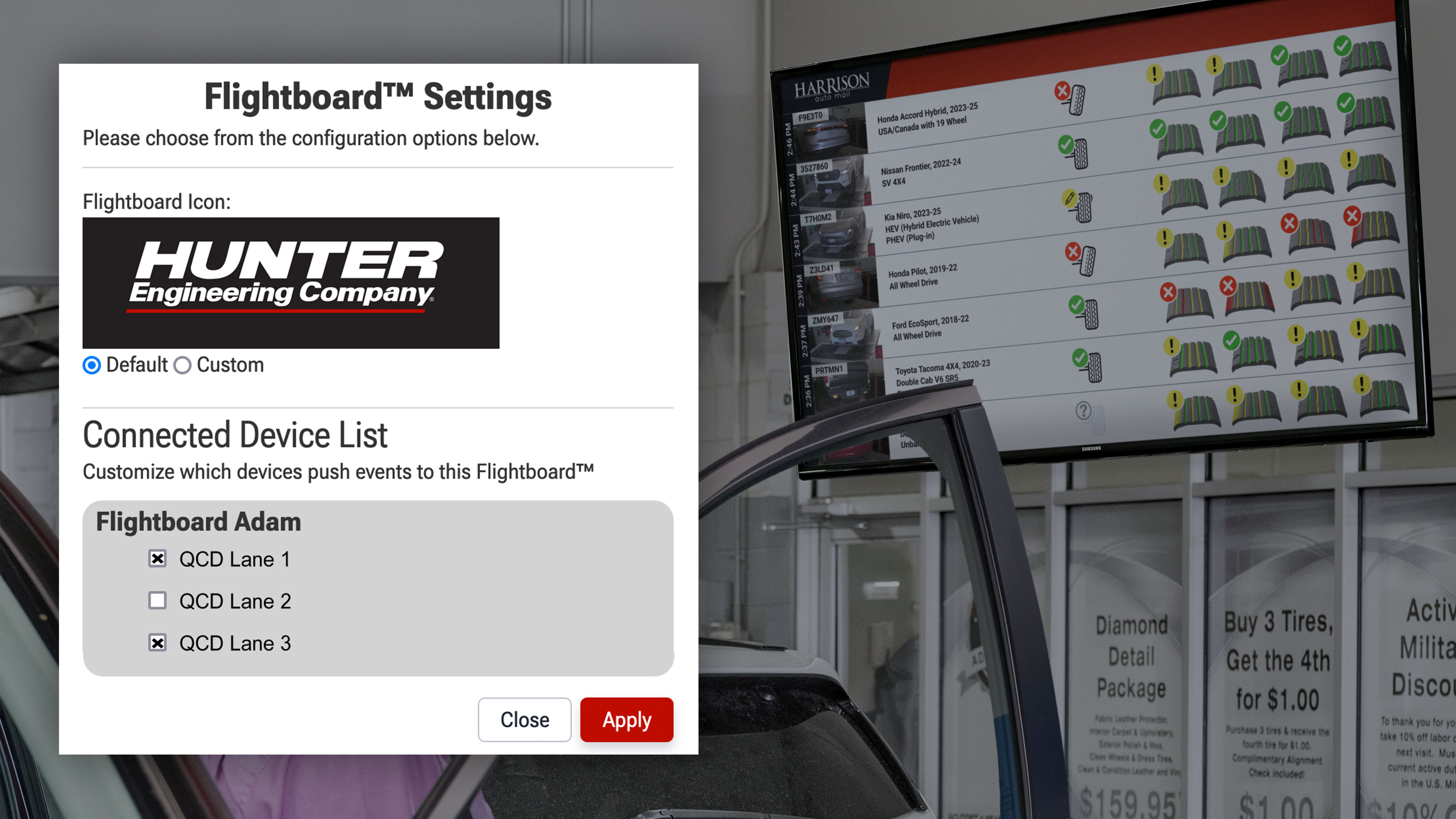

Flightboard™ digital results display

Provide complete customer transparency

Show your customers immediate alignment and tire tread inspection results before ever talking to the service writer.

Exclude dealer/non-customer traffic

Upload a list of plates to ignore, keeping dealer vehicles out of Quick View for more accurate performance reporting.

Refreshed visuals

New icons and tire renders are eye-catching and give a clear call to action. Take immediate action on pass/fail, add specs in one click for a result, and know when a re-run is needed or if traffic flow needs addressing.

Easy management

Generate a shareable link to display on any screen location without login. Mix and match lanes to make multiple custom Flightboards.

Calculate your return on investment

View your rapid return on investment with automatic alignment inspection

Your Return On Investment

Input your vehicles/day and profits to calculate your payback

Please use Chrome and landscape view for best print results

| Additional Daily Profit |

|

|---|---|

| Annual Return |

|

| Equipment Investment |

$

|

| Equipment Payback |

months!

|

Notes

- One alignment system per 50 cars inspected is typically required to support additional alignment opportunities

- See current tax code. In many cases, full purchase price of equipment is tax-deductible.

- Concrete and site construction work are not included in the price of the equipment.

- Payback calculation: (Equipment Investment) / (Cars/day X failure rate X acceptance rate X typical profit X 5.5 day/week X 4 wks/mo)

Contact for pricing or demo

Hunter Finance™

Powered by GreatAmerica Financial Services

Financing is a great way to lower your upfront cost, and get immediate return on investment. Hunter Financing™ is available in the U.S. and facilitated by GreatAmerica Financial Services.

- Simpler and faster process than a traditional loan

- 25+ years financing the automotive industry

- Knowledgeable about your specific needs

Hunter Credit™

Powered by EasyLease Express™

Leasing is a great option to lower your upfront cost, and get immediate return on investment. Hunter Credit™ is available in Canada through EasyLease Express™.

- Same-day approvals

- Expense your lease payments to lower your taxable income

- Industry-focused with knowledge about your specific needs

Access and deliver printouts

Hands-on customer results can be printed or viewed on a tablet.

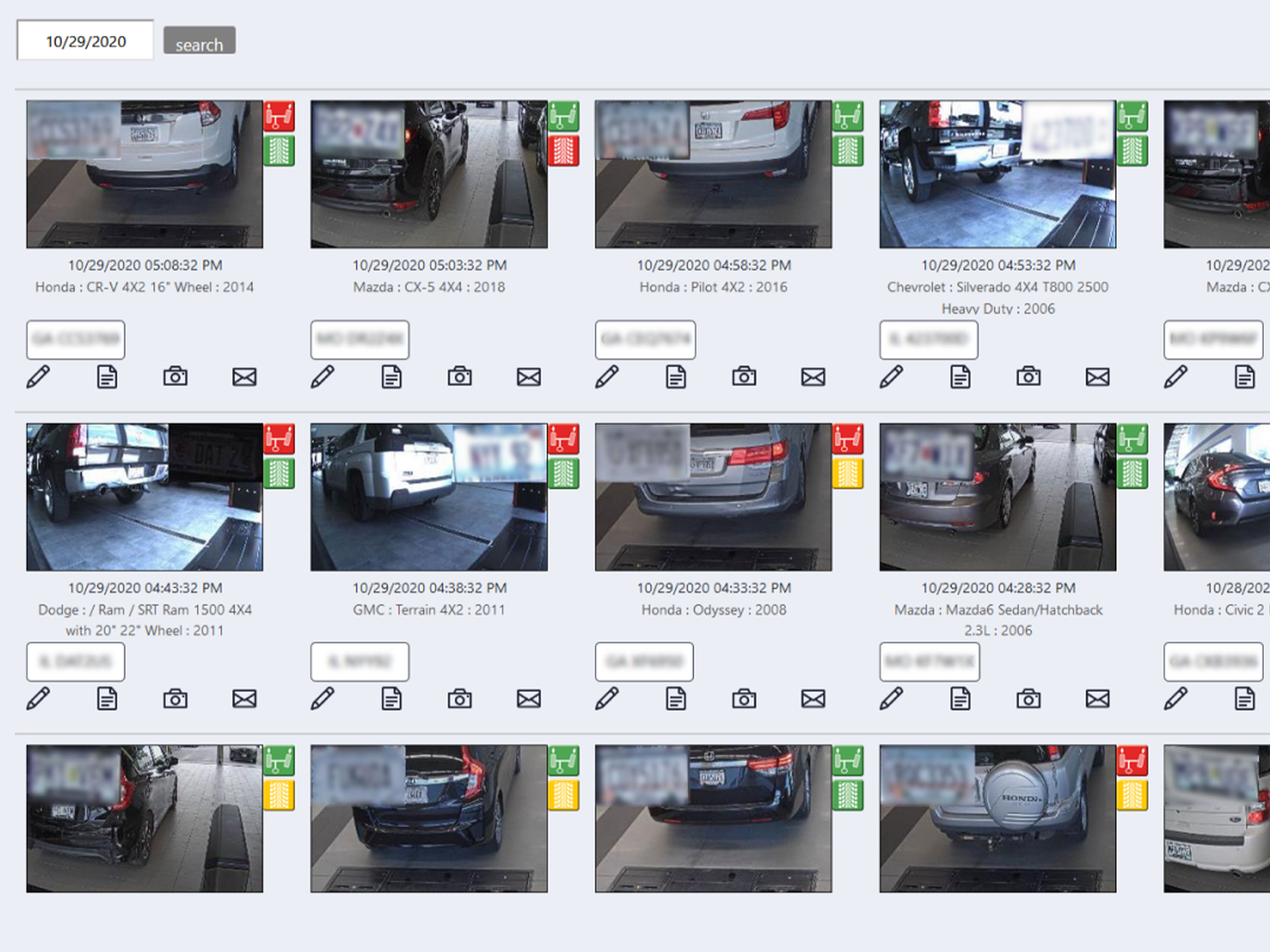

Quick View

Shop favorite

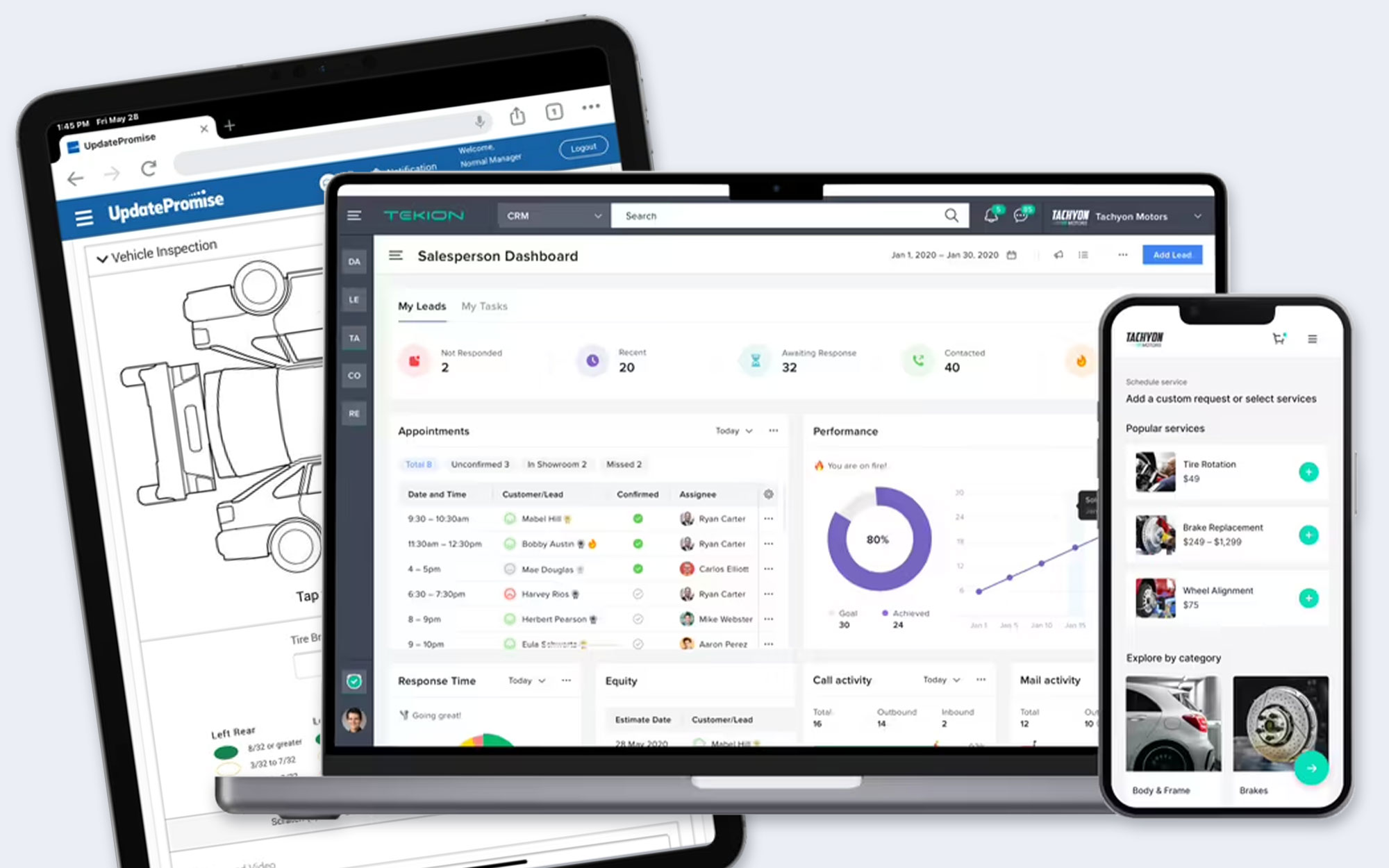

Take action with your inspection results with Quick View. This dashboard lets you easily find the customer's vehicle and navigate to individual results, body damage, or vehicle spec editing.

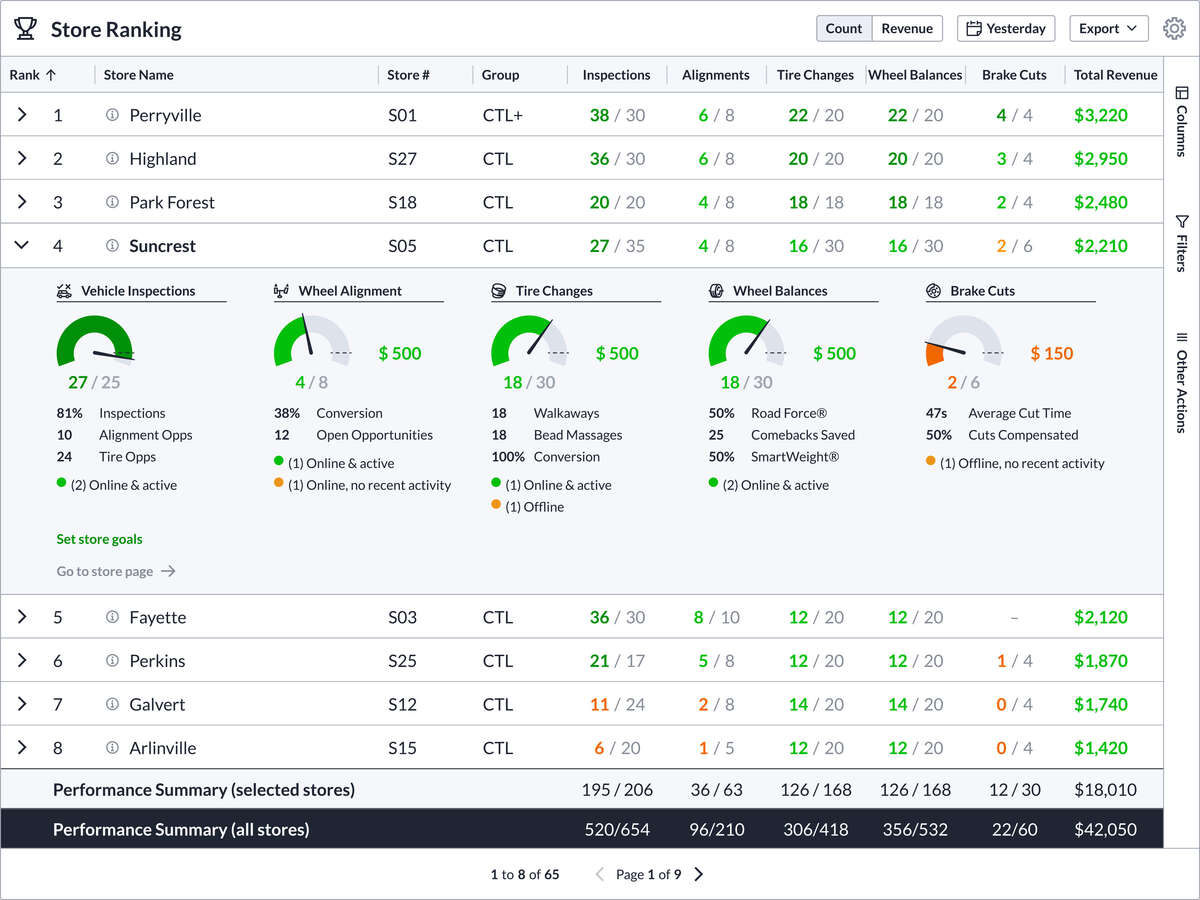

Multi-store view

See all your stores together, with performance ranked and equipment inventoried.

Receive daily reports

Push reports delivered daily by email and text help you view opportunities and rates, measure alignment conversions, and set goals and track performance.

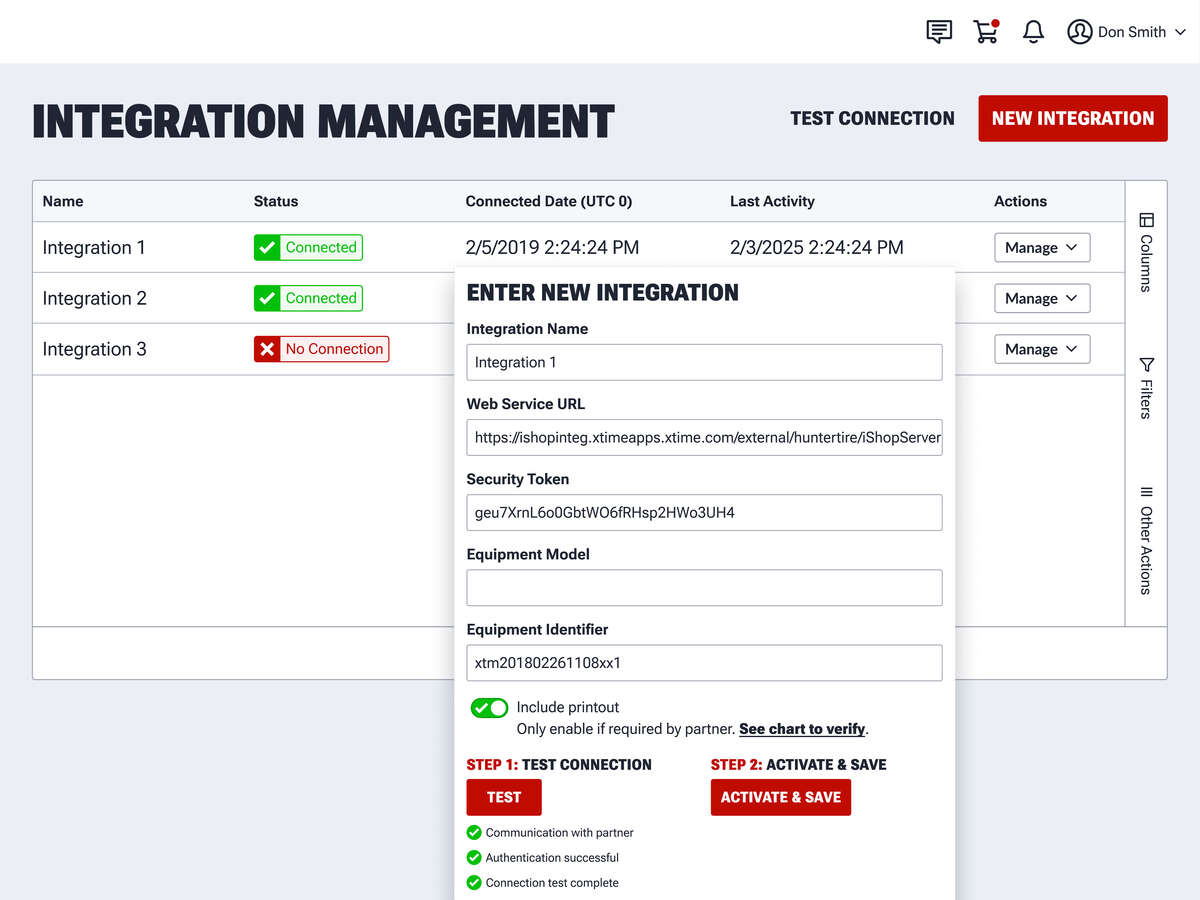

Manage partner integrations

Send inspection results directly to your dealer or shop management system, MPI software, tire program or any connected integration partner. Connecting and monitoring is easier than ever.

Exclude non-customer vehicles

Clean up noise in your results by uploading a list of license plates to ignore inspections of dealer courtesy vehicles or other non-customer vehicles.

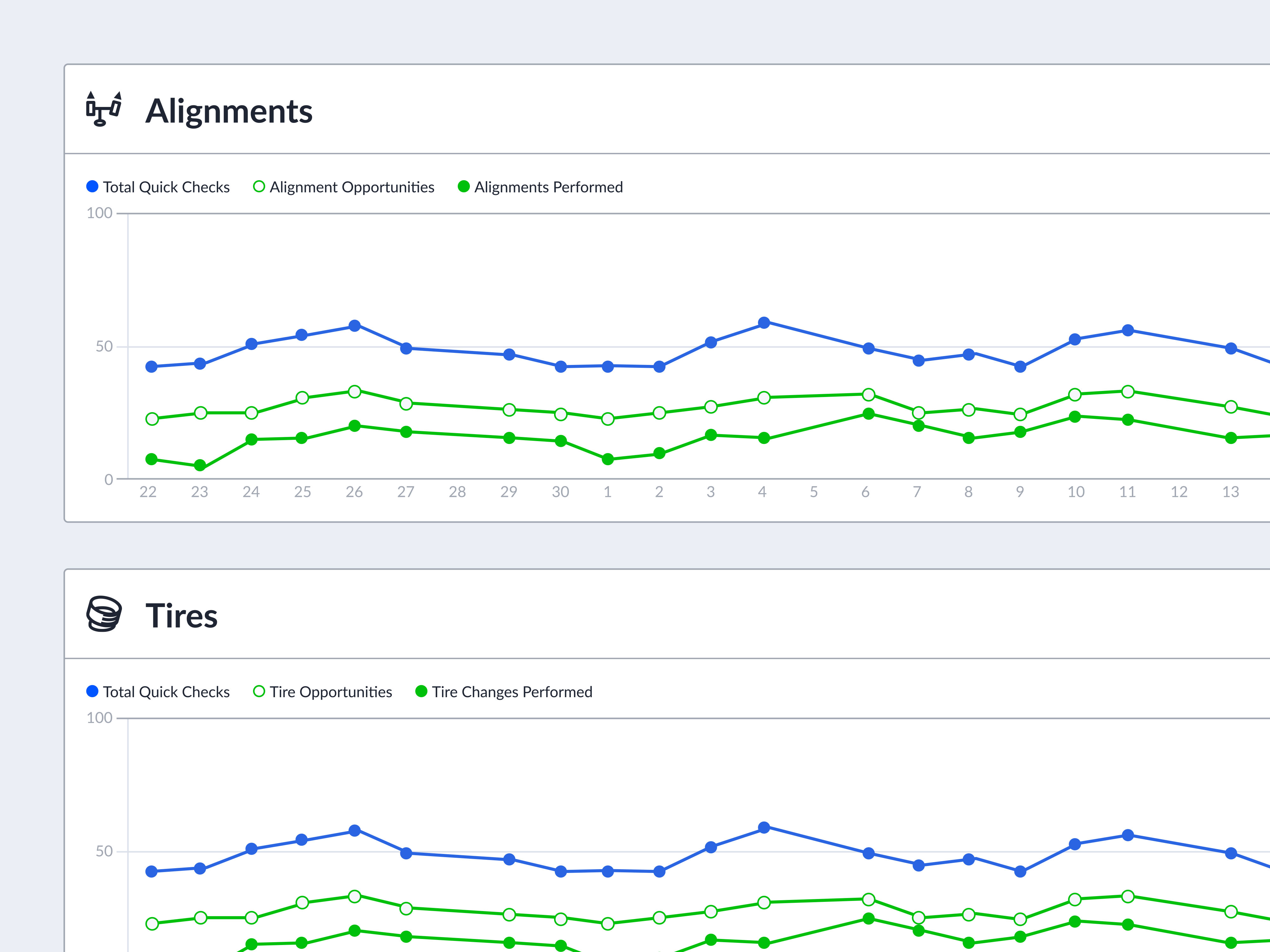

Chart your performance

View vehicle inspection trends and measure total events, alignment and tread opportunities, and alignments or tire changes performed over custom time ranges.

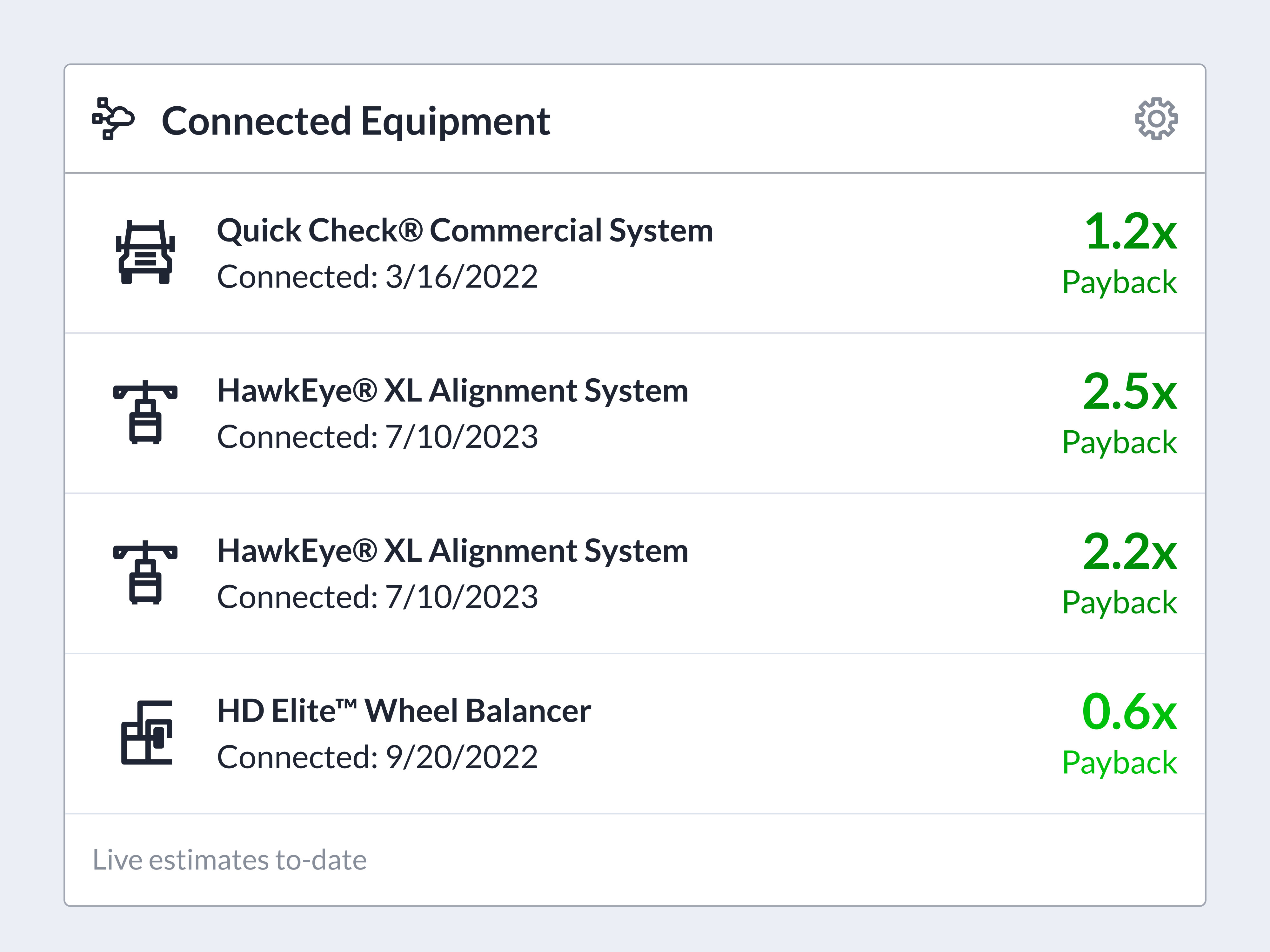

Monitor you ROI

See your equipment payback in real time.

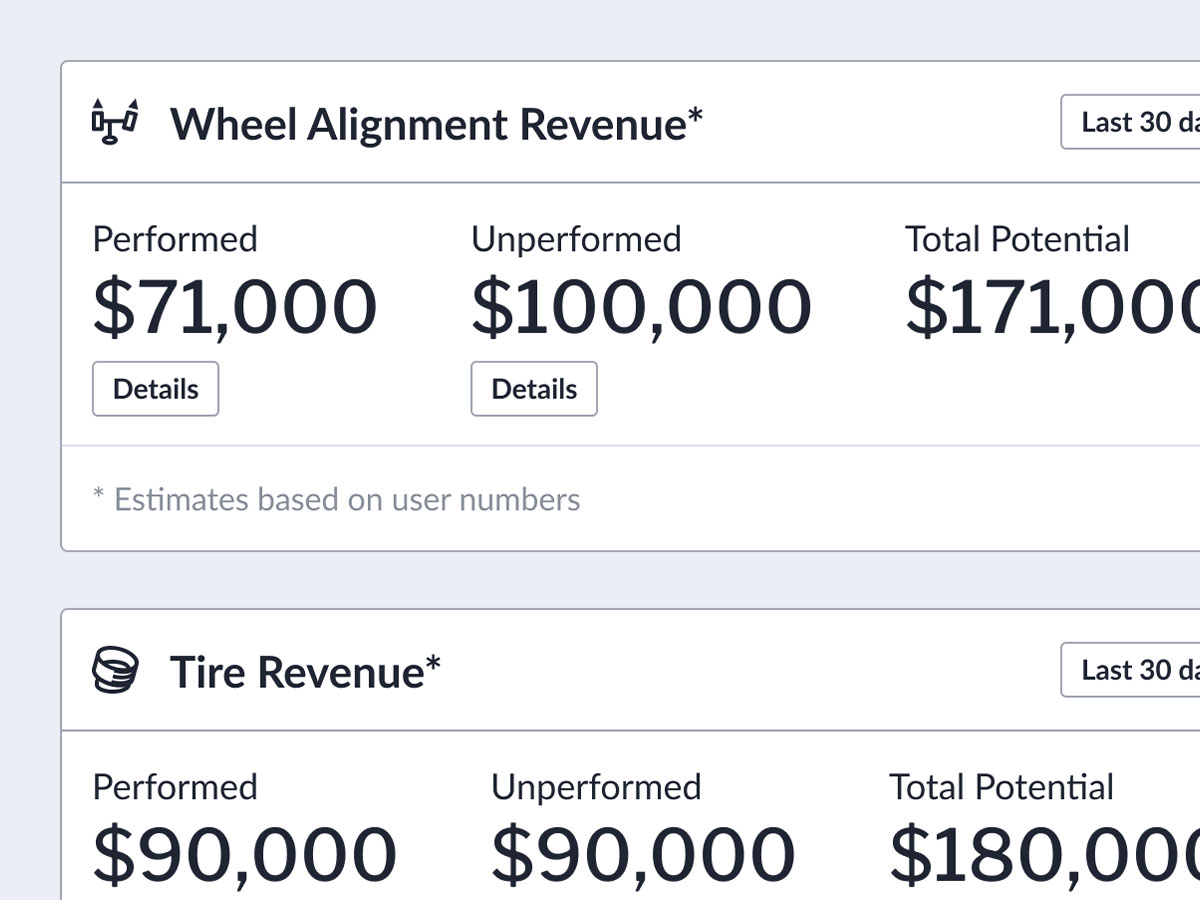

Track revenue

Track your profits and potential amount if all needed services were sold.

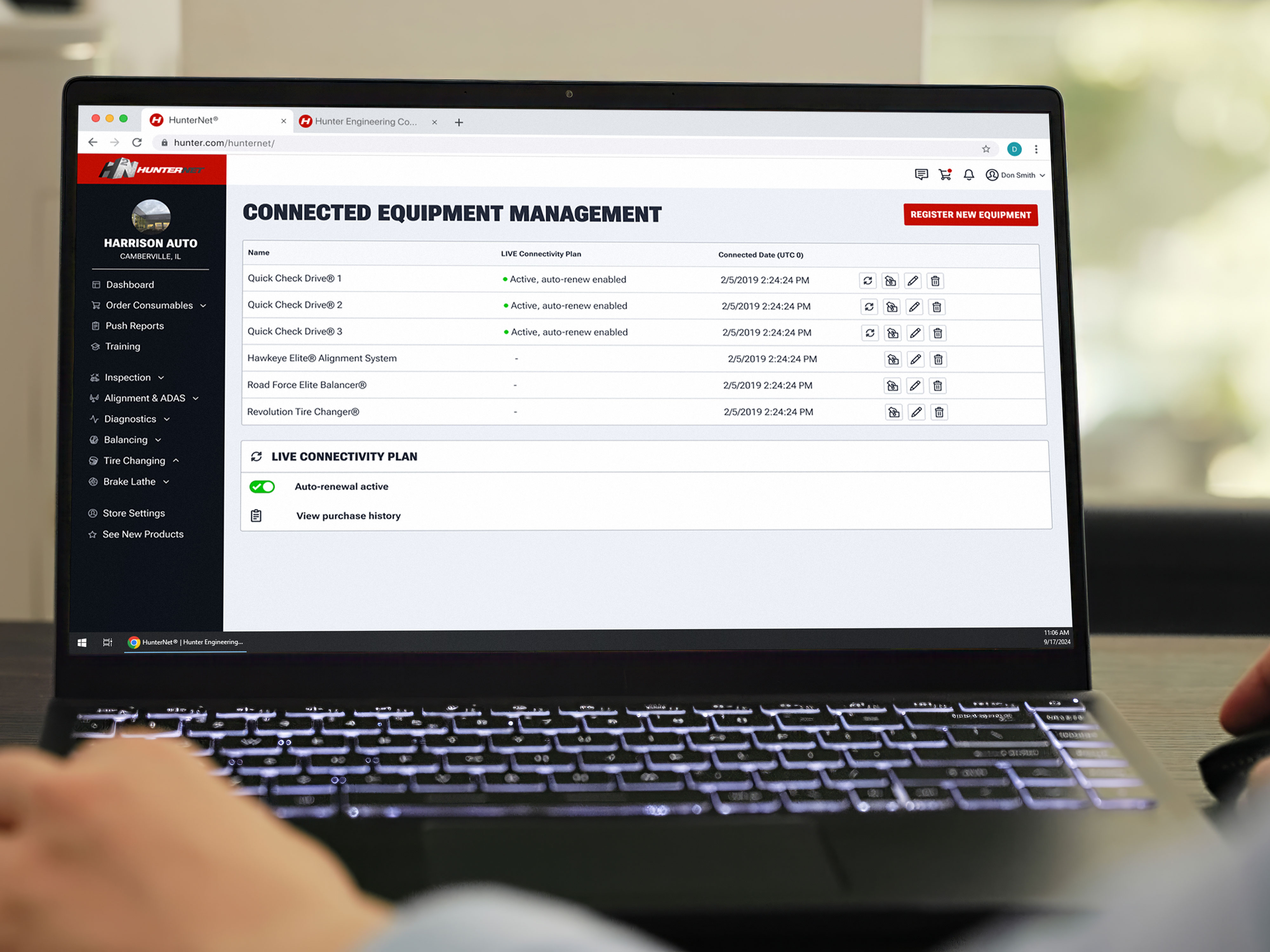

HunterNet® 2 Portal

Equipment intelligence tools help you manage your business and profits in real time.

Connect with your preferred integration partner

Hunter equipment integrates with 30 leading industry partners to span the entire customer service experience, including virtually every major dealer management and shop management system.

Seeing is believing

Quick Check Drive® units come with an external camera to automatically capture a high quality image of the vehicle's license plate as it drives through, which is used to determine OEM specs in most cases. The external camera can be placed in the exact location needed to prevent glare — useful for challenging license plate designs.

Shoot down false damage claims

40+ high-quality images are captured from 4 different camera angles

90-day image storage

Thousands of dollars saved in false damage claims

Immediate access to your images — no third-party requests

Intuitive Damage-Cam interface displays vehicle information and date of service. 90-day image storage standard. Yearly subscription charges apply.

Need help ordering parts?

We are ready to help!

Receive Same-Day or Next-Day Shipping

Receive Same-Day or Next-Day Shipping

![]() Parts Built for Quality and Performance

Parts Built for Quality and Performance

![]() Seamless and Reliable Installation

Seamless and Reliable Installation

![]() Unmatched Support, Every Step of the Way

Unmatched Support, Every Step of the Way

Choose the right inspection equipment for your shop

Light-Duty

Class I Vehicles

-

- QCD alignment sensors

- QTEF tread depth

- LIVE1 Inspection Live Console

Suitable for wheel assemblies up to 32 in. and up to 7,000-lb. axle weight.

-

- Compact

- Sedan

- SUV

- Pickup

- Transit Van

Medium-Duty

Up to Class V Vehicles

- QCD alignment sensors

- QTHD tread depth

- WU592MD WinAlign® console

Suitable for wheel assemblies up to 32 in. and from 7,000-20,000 lb. axle weight.

- RV

- Dual-Axle Pickup

- Delivery Van

Heavy-Duty

Class VI Vehicles and Above

- QCHD alignment sensors

- QTHD tread depth

- WU592HD WinAlign® console

Suitable for wheel assemblies greater than 30 in. and from 7,000-20,000 lb. axle weight.

-

- Box Trucks

- Dump Trucks

- Heavy Utility Vehicles

- Municipal and Commercial Buses

- Over-the-Road Tractor Trailers

Are you ready for every profitable service opportunity that enters your shop?

Unmanned Commercial Inspection

Instant, unmanned inspection for heavy-duty dealers, repair shops and fleets

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Documents

-

Brochures

-

Ordering Guides

-

Specification Sheets

Receive same- or next-day service

Get a free quote or on-site demo

Register for ASE-accredited training

General information & questions

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

From raw steel to finished product. When you choose Hunter, you're investing in more than 1,000 American workers.